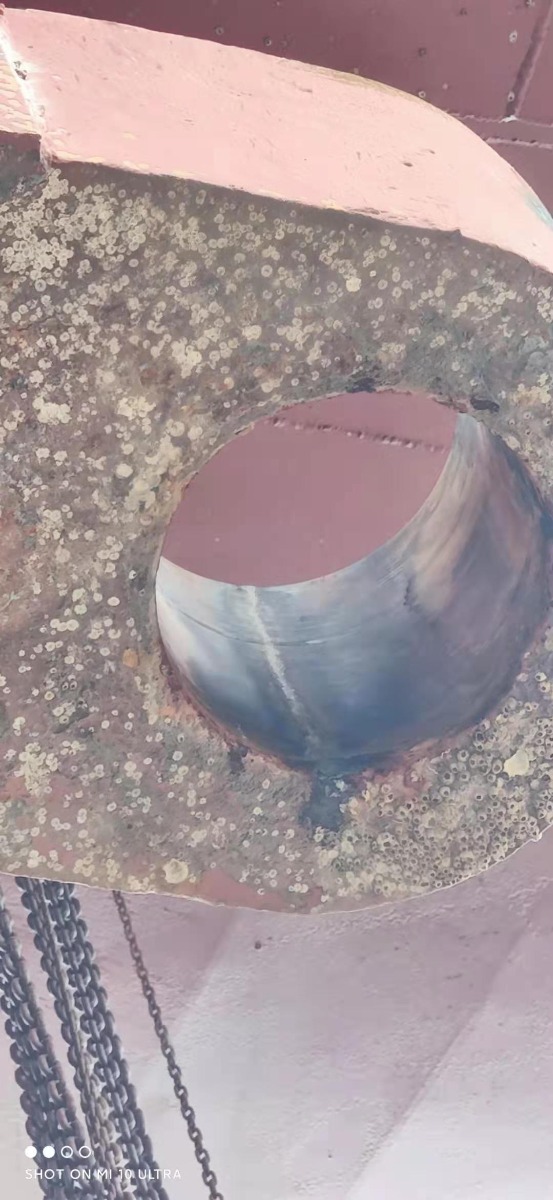

Tail shaft boring, tail shaft adjustment, rudder blade boring, large ship tail shaft adjustment, machining, finishing

The rudder hole includes a coaxial connected taper hole and a short hole from the outside to the inside,

The process steps are as follows

(1) After the fabrication of the rudder blade is completed, the rudder blade shall be leveled, the four sides shall be padded with piers, and the steel ruler and laser theodolite shall be used to adjust the center of the four sides and two holes,

(2) According to the center line of the rudder blade provided in the previous section, the steel wire shall be drawn and aligned at the center of the big end of the rudder stock steel casting and the bottom sealing plate,

(3) Insert the boring bar;

(4) After straightening the boring bar, set the cutter and bore the hole;

(5) After finishing boring, remove boring row, cut horseshoe, polish, brush oil hole plane, pull steel wire, and recheck hole concentricity based on process benchmark screw of rudder pin and rudder stock pedestal

Technical support guidance: Hongfeng 13777192223

86agency undertake international import & export of mechanical and

electrical equipment, ships, offshore projects, floating cranes

Project and equipment,material construction expediting agent in China

Relevant affairs progress management consulting

Email: nt@udship.com OR js001@86agency.com

WeChat:+86 13186588840

Mobile Phone:+86 13186588840

Announcement Account of 86agency Escrow Settlement Account: 545672102317

For Ship Trading Process!

Related transaction contacts +86 18115303233

Customer contact:js001@86agency.com

Customer contact:js001@86agency.com